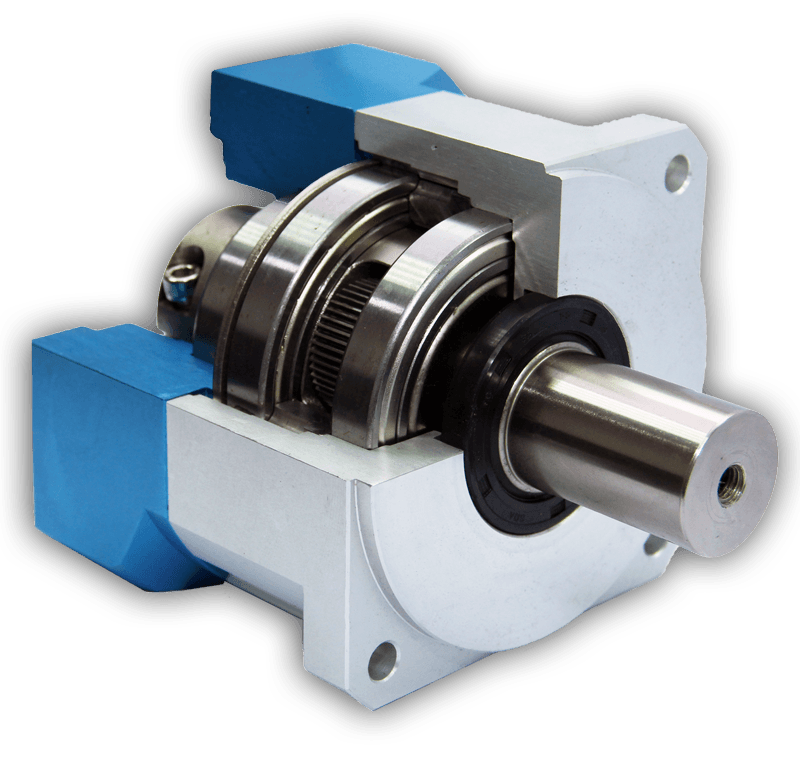

Varitron DL Inline Precision planetary gearbox promise dynamic performances with low backlash. An impressive assortment of servo grade planetary gearbox for our inline series. Providing the ultimate flexibility for our customers.

Features

- High Precision Gear -

The planetary gear and sun gear are manufactured from high quality Ni-Cr-Mo alloy steel. Precision machined and carburized, then for precision tooth grinding or skiving assures gears high precision.

- Modular Deisgn of Motor Connection Plate -

The special modular design of motor connection plate is suitable for any brand and any type of servomotor. Manufactured from aluminum alloy, its surface is anodized treated for upgrading environmental-resistant and corrosion-resistant capability.

- Single-piece Gearbox & Advanced Surface Treatment -

The gearbox and internal gear ring are single price design and constructed, which is manufactured from Cr-Mo alloy steel, and tempered for high torque output. Gearbox surface is anti-corrosive treated for upgrading environmental resistant and corrosionresistant capability.

- Modular Input Shaft -

Modular input shaft design and motor shaft are coupled through a dynamic balanced collar clamping mechanism to ensure connection concentricity and zero slip power transmission at high speed.

- Integrated Planetary Arm Bracket -

The planetary arm bracket and the output shaft are single piece design constructed to increase torsional rigidity and accuracy. The entire structure is one-time machined for controlling accuracy in the specified tolerance.

|

Model Number |

DL Series High Precision Planetary Gearbox |

|

Speed Reduction Method |

Planetary gear mechanism with designed tooth profile |

|

Efficiency |

95% per stage gearbox |

|

Shock Load |

300% as there are only compressive forces rather than shear forces on the tooth |

|

Gear box Mounting |

Flange Mounting, Foot mounting parts sold separately |

|

Reduction Ratio |

Up to 1:10 per stage 1:1000 on 3-stages |

|

Capacity Range |

100Watt to 11,000Watt |

|

Enclosure |

Totally enclosed IP55 |

|

Power Source |

Servo motor, stepper motor |

|

Backlash |

Single Stage: below 5arcmin Double Stages: Below 8arcmin |

|

Reduction Gearbox Lubrication Method |

High viscosity anti-separation grease |

|

Method of Coupling with Driven Machine |

Coupling, gears, chain sprocket or belt |

|

Standard |

CE, UL, CSA, ISO 9001, ISO14001 |

|

Warranty |

1 Year Limited Warranty |

Technical

Information

|

Specification |

Ratio (Stages) |

DL060 |

DL090 |

DL120 |

DL150 |

|

|

Instantaneous Max. Output Torque T2B (Nm) |

3/9/10/12/21/30 |

120 |

420 |

780 |

1428 |

|

|

4/15/16/20/25/40 |

153 |

504 |

918 |

1680 |

||

|

7/28/35/70/100 |

132 |

498 |

855 |

1560 |

||

|

5/50 |

141 |

465 |

876 |

1608 |

||

|

Defined Output Torque T2N (Nm) |

3/9/10/12/21/30 |

40 |

140 |

260 |

476 |

|

|

4/15/16/20/25/40 |

51 |

168 |

306 |

560 |

||

|

7/28/35/70/100 |

44 |

166 |

285 |

520 |

||

|

5/50 |

47 |

155 |

292 |

536 |

||

|

Reduction Ratio |

L1: 1 Stage 單段 |

3 / 4 / 5 / 7 / 10 |

||||

|

L2: 2 Stage 雙段 |

9 / 12 / 15 / 16 / 20 / 21 / 25 / 28 / 30 / 35 / 40 / 49 / 50 / 70 |

|||||

|

L3: 3 Stage 三段 |

100 / 200 / 250 |

|||||

|

Defined Input Rotational Speed n1N (rpm) |

3/4/5 (L1) |

3300 |

2600 |

2300 |

2200 |

|

|

7/10 (L1) |

4000 |

2900 |

2700 |

2700 |

||

|

12~40 (L2) |

4400 |

3200 |

3000 |

3000 |

||

|

50 (L2) |

4800 |

3600 |

3300 |

3200 |

||

|

70~100 (L2) |

5500 |

4200 |

3900 |

3500 |

||

|

Backlash (arcmin) |

3~10 (L1) |

≤10 |

≤10 |

≤10 |

≤10 |

|

|

12~100 (L2) |

≤12 |

≤12 |

≤12 |

≤12 |

||

|

Torsional Rigidity (Nm/arcmin) |

3~100 (L1,L2) |

7 |

11 |

27 |

48 |

|

|

Allowable Radial Force F2rB2 (N) |

3~100 (L1, L2) |

750 |

5400 |

7500 |

14000 |

|

|

Allowable Axial Force F2aB2(N) |

3~100 (L1, L2) |

545 |

4500 |

6450 |

12000 |

|

|

Full Load Efficiency % |

3~10 (L1) |

≥97 |

||||

|

12~100 (L2) |

≥94 |

|||||

|

Service Life Lh2 (hrs) |

3~100 (L1, L2) |

20000 |

||||

|

Weight (kgs) |

3~10 (L1) |

1.1 |

3.5 |

6 |

16 |

|

|

12~100 (L2) |

1.6 |

4.5 |

7.2 |

20 |

||

|

Noise (db) |

|

65 |

64 |

64 |

64 |

|

|

Temperature °C |

|

(-15°C ~ +90°C) |

||||

|

Protection Rank |

|

IP64 / IP65 (IP66 by request 訂購製作) |

||||

|

Lubricating Oil |

|

Synthetic Lubricant 合成潤滑油 ISO VG220 |

||||

|

Moment Of Inertia J1 (kg.cm) |

Stages |

Ratio |

|

|||

|

L1

|

3 |

0.31 |

0.4 |

5.9 |

10.5 |

|

|

4 |

0.3 |

0.6 |

5.09 |

9.1 |

||

|

5 |

0.29 |

0.59 |

4.93 |

8.85 |

||

|

7 |

0.28 |

0.58 |

4.83 |

8.85 |

||

|

10 |

0.27 |

0.57 |

4.81 |

8.46 |

||

|

L2 |

9 |

0.29 |

0.56 |

4.91 |

9.02 |

|

|

12 |

0.3 |

0.58 |

5.1 |

9.01 |

||

|

16 |

0.3 |

0.6 |

5.09 |

9.01 |

||

|

20 |

0.3 |

0.6 |

5.07 |

9.02 |

||

|

25 |

0.29 |

0.59 |

4.91 |

8.83 |

||

|

28 |

0.3 |

0.59 |

5.07 |

9.01 |

||

|

35 |

0.3 |

0.58 |

4.91 |

8.82 |

||

|

40 |

0.27 |

0.56 |

4.8 |

8.45 |

||

|

50 |

0.27 |

0.56 |

4.8 |

8.45 |

||

|

70 |

0.27 |

0.56 |

4.8 |

8.45 |

||

|

100 |

0.27 |

0.56 |

4.8 |

8.45 |

||

Designation

|

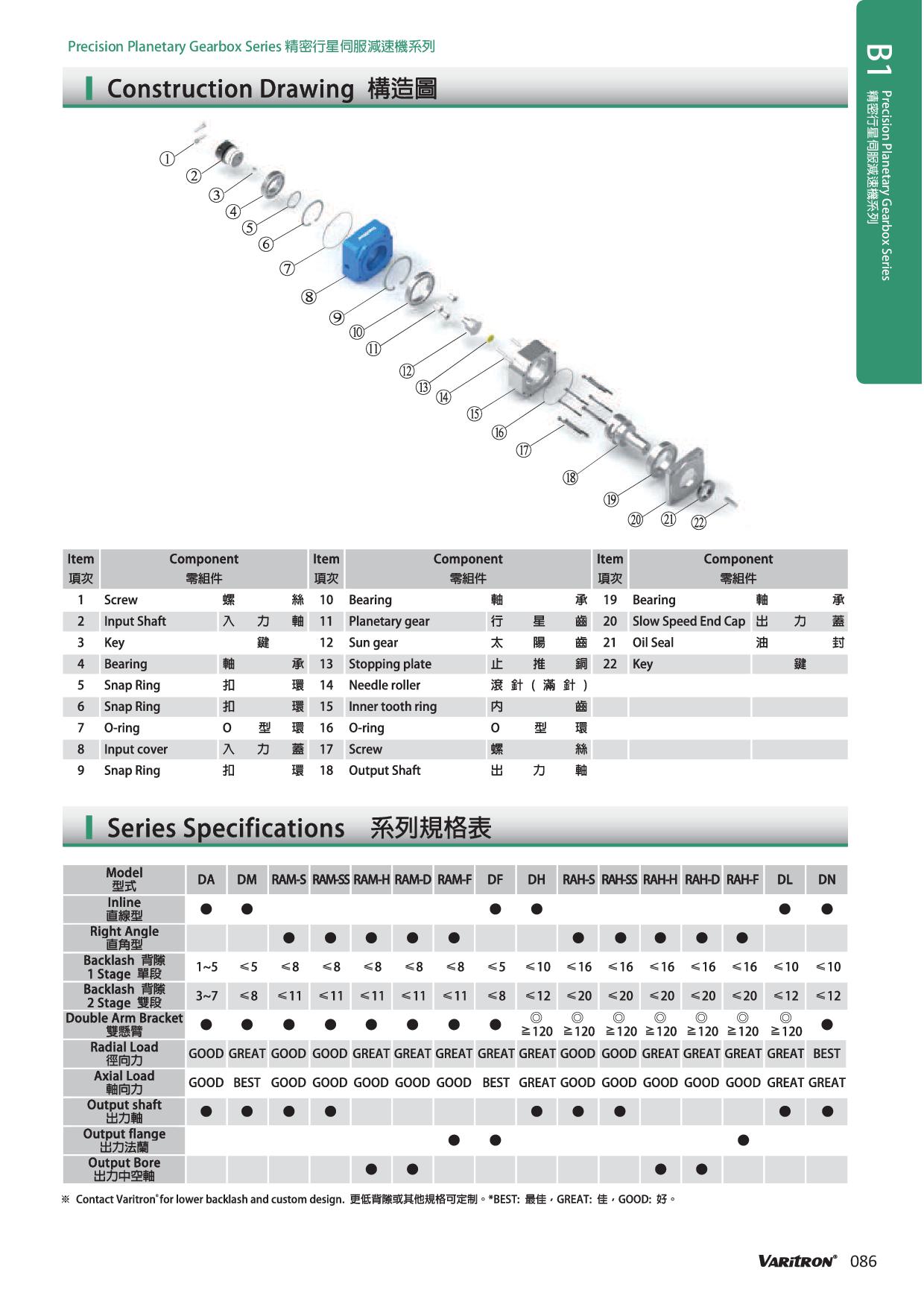

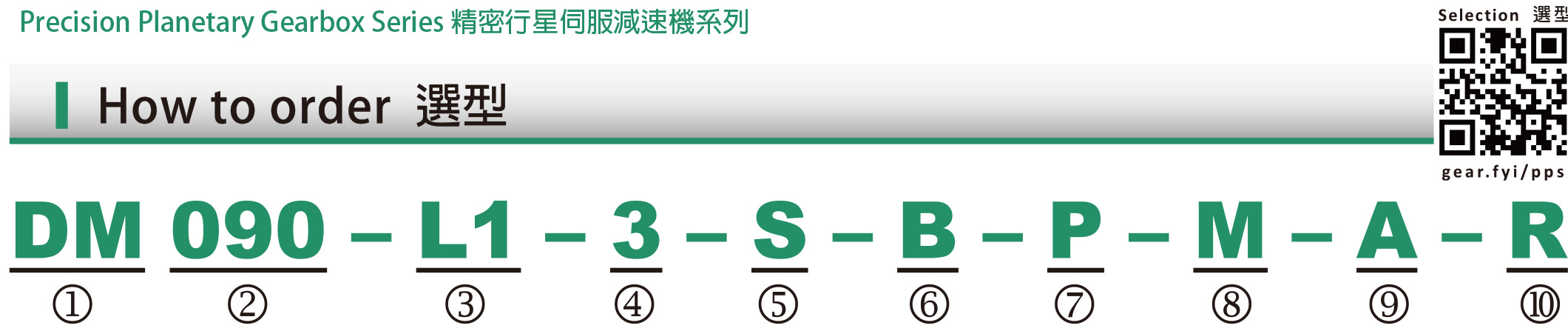

j |

Model |

DA: Helical Gear High Precision Planetary Gearbox DM:Precision Planetary Gearbox DML:Precision Round Body Planetary Gearbox DF:Precision Flange Type Planetary Gearbox DH:Standard Precision Planetary Gearbox DL:Standard Precision Round Body Planetary Gearbox DN:High R-A Load Standard Precision Planetary Gearbox RAM-S:Precision Shaft Output Spiral Bevel Gearbox RAM-SS:Precision Double Shaft Spiral Bevel Gearbox RAM-H:Precision Hollow Shaft Spiral Bevel Gearbox RAM-D: Precision Clamping Shaft Spiral Bevel Gearbox RAM-F: Precision Flange Spiral Bevel Gearbox RAH-S: Standard Precision Shaft Output Spiral Bevel Gearbox RAH-SS:Standard Precision Double Shaft Spiral Bevel Gearbox RAH-H:Standard Precision Hollow Shaft Spiral Bevel Gearbox RAH-D:Standard Precision Clamping Shaft Spiral Bevel Gearbox RAH-F: Standard PrecisionFlange Spiral Bevel Gearbox |

|

|

k |

Frame Size |

042,060,070,080,090,120,150,180,220… Refer to Gearbox Quick Selection Table Page 89. |

|

|

l |

Stage |

L1, L2, L3 |

|

|

m |

Ratio |

L1: 3 / 4 / 5 / 7 / 10 L2: 9 / 12 / 15 / 16 / 20 / 21 / 25 / 28 / 30 / 40 / 49 / 50 / 70 L3: 36 / 45 / 60 / 75 / 80 / 150 / 200 / 300 / 400 / 500 / 700 / 1000 |

|

|

n |

Motor Shaft Diameter (S) |

Customized according to customer requirement. |

|

|

o |

Motor Pilot Diameter (B) |

Customized according to customer requirement. |

|

|

p |

Motor Guide Depth (P) |

Customized according to customer requirement. |

|

|

q |

Installing Screw P.C.D (M) |

Customized according to customer requirement. |

|

|

r |

Installing Screw Size (A) |

Customized according to customer requirement. |

|

|

s

|

Motor Shaft Length (R) |

Customized according to customer requirement. |

|

Applications

Application of Planetary Gearbox

Planetary Gearboxes are used on high precision motion control application that require a high torque, high torsional stiffness and low backlash the specifics of which will vary by application.

Planetary gearboxes increase the torque by the stage of reduction ratio, making it possible to run the motor at a higher, more efficient speed. The inertia reflected back to the motor is reduced for increased stability. Using a planetary gearbox allow machine builders using a smaller, less expensive motion control package.

The application of planetary gearboxes covers the entire range of automation. It's frequently found in "pick and place" systems, loading and unloading gantry robots, driving rotary and linear actuators, in packaging machineries, positioning tables in medical equipment.

Address:No.45, Lane 171, Chung Shin Road, Wuku District, New Taipei City, Taiwan

Tel:+886-2-29889598

Fax:+886-2-29850998

Email:[email protected]

Copyright 2014 © Varitron Engineering (Taiwan) Co., Ltd. All Rights Reserved.