DN Series high Radian Axials load inline Precision planetary servobox gearbox promise dynamic performances with low backlash.

Features

- High Precision Gear -

The planetary gear and sun gear are manufactured from high quality Ni-Cr-Mo alloy steel. Precision machined and carburized, then for precision tooth grinding or skiving assures gears high precision.

- Modular Deisgn of Motor Connection Plate -

The special modular design of motor connection plate is suitable for any brand and any type of servomotor. Manufactured from aluminum alloy, its surface is anodized treated for upgrading environmental-resistant and corrosion-resistant capability.

- Single-piece Gearbox & Advanced Surface Treatment -

The gearbox and internal gear ring are single price design and constructed, which is manufactured from Cr-Mo alloy steel, and tempered for high torque output. Gearbox surface is anti-corrosive treated for upgrading environmental resistant and corrosionresistant capability.

- Modular Input Shaft -

Modular input shaft design and motor shaft are coupled through a dynamic balanced collar clamping mechanism to ensure connection concentricity and zero slip power transmission at high speed.

- Integrated Planetary Arm Bracket -

The planetary arm bracket and the output shaft are single piece design constructed to increase torsional rigidity and accuracy. The entire structure is one-time machined for controlling accuracy in the specified tolerance.

|

DN Gearbox Model Number |

DN Series High Radian load Axials Load Precision Planetary Gearbox DN060, DN080, DN100, DN150 |

|

Speed Reduction Method |

Planetary gear mechanism with designed tooth profile |

|

Efficiency |

95% per stage gearbox |

|

Shock Load |

300% as there are only compressive forces rather than shear forces on the tooth |

|

Gear box Mounting |

Flange Mounting, Foot mounting parts sold separately |

|

Reduction Ratio |

Up to 1:10 per stage 1:1000 on 3-stages |

|

Capacity Range |

100Watt to 11,000Watt |

|

Enclosure |

Totally enclosed IP55 |

|

Power Source |

Servo motor, stepper motor |

|

Backlash |

Single Stage: below 5arcmin Double Stages: Below 8arcmin |

|

Reduction Gearbox Lubrication Method |

High viscosity anti-separation grease |

|

Method of Coupling with Driven Machine |

Coupling, gears, chain sprocket or belt |

|

Standard |

CE, UL, CSA, ISO 9001, ISO14001 |

|

Warranty |

1 Year Limited Warranty |

Technical

Information

|

Specification |

Ratio (Stages) |

DN060 |

DN080 |

DN100 |

|

|

Instantaneous Max. Output Torque T2B (Nm) |

10/100 |

120 |

345 |

780 |

|

|

16/4/20/28/36/40 |

153 |

405 |

918 |

||

|

81/49/7/9/63/70/90 |

132 |

396 |

855 |

||

|

5/45/50/35/25 |

141 |

378 |

876 |

||

|

Defined Output Torque T2N (Nm) |

10/100 |

40 |

115 |

260 |

|

|

4/16/20/28/36/40 |

60 |

135 |

306 |

||

|

7/9/49/63/70/81/90 |

50 |

132 |

285 |

||

|

5/25/35/4/50 |

55 |

126 |

292 |

||

|

DN Gearbox Reduction Ratio |

L1: 1 Stage 單段 |

4 / 5 / 7 / 9 / 10 |

|||

|

L2: 2 Stage 雙段 |

16 / 20 / 25 / 28 / 30 / 35 / 36 / 40 / 45 / 49 / 50 / 63 / 70 / 81 / 90 |

||||

|

L3: 3 Stage 三段 |

100 / 200 / 250 |

||||

|

Defined Input Rotational Speed n1N (rpm) |

4/5 (L1) |

3300 |

3000 |

2300 |

|

|

7~10 (L1) |

4000 |

3300 |

2700 |

||

|

16~40 (L2) |

4400 |

3500 |

3000 |

||

|

50 (L2) |

4800 |

4000 |

3300 |

||

|

70~100 (L2) |

5500 |

4700 |

3900 |

||

|

Backlash (arcmin) |

4~10 (L1) |

≤10 |

≤10 |

≤10 |

|

|

16~100 (L2) |

≤12 |

≤12 |

≤12 |

||

|

Torsional Rigidity (Nm/arcmin) |

4~100 (L1,L2) |

7 |

8 |

27 |

|

|

Allowable Radial Force F2rB2 (N) |

4~100 (L1,L2) |

2800 |

7200 |

8000 |

|

|

Allowable Axial Force F2aB2 (N) |

4~100 (L1,L2) |

2200 |

5000 |

5600 |

|

|

Full Load Efficiency % |

4~10 (L1) |

≥97 |

|||

|

16~100 (L2) |

≥94 |

||||

|

Service Life Lh2 (hrs) |

4~100 (L1,L2) |

20000 |

|||

|

Weight (kgs) |

4~10 (L1) |

1.3 |

2.3 |

6 |

|

|

16~100 (L2) |

1.6 |

3.3 |

7.2 |

||

|

Noise (db) |

|

65 |

64 |

64 |

|

|

Temperature °C |

|

( -15°C ~ +90°C ) |

|||

|

Protection Rank |

|

IP64 |

|||

|

Lubricating Oil |

|

Synthetic Lubricant ISO VG220 |

|||

|

Moment Of Inertia J1 (kg.cm) |

Stage |

Ratio |

|

||

|

L1

|

3 |

0.31 |

0.35 |

5.9 |

|

|

4 |

0.3 |

0.33 |

5.09 |

||

|

5 |

0.29 |

0.33 |

4.93 |

||

|

7 |

0.28 |

0.31 |

4.83 |

||

|

9 |

0.28 |

0.31 |

4.83 |

||

|

10 |

0.28 |

0.31 |

4.83 |

||

|

L2 |

16 |

0.3 |

0.3 |

5.09 |

|

|

20 |

0.3 |

0.3 |

5.07 |

||

|

25 |

0.29 |

0.3 |

4.91 |

||

|

28 |

0.3 |

0.3 |

5.07 |

||

|

35 |

0.3 |

0.3 |

4.91 |

||

|

40 |

0.27 |

0.3 |

4.8 |

||

|

50 |

0.27 |

0.3 |

4.8 |

||

|

70 |

0.27 |

0.3 |

4.8 |

||

|

100 |

0.27 |

0.3 |

4.8 |

||

Designation

|

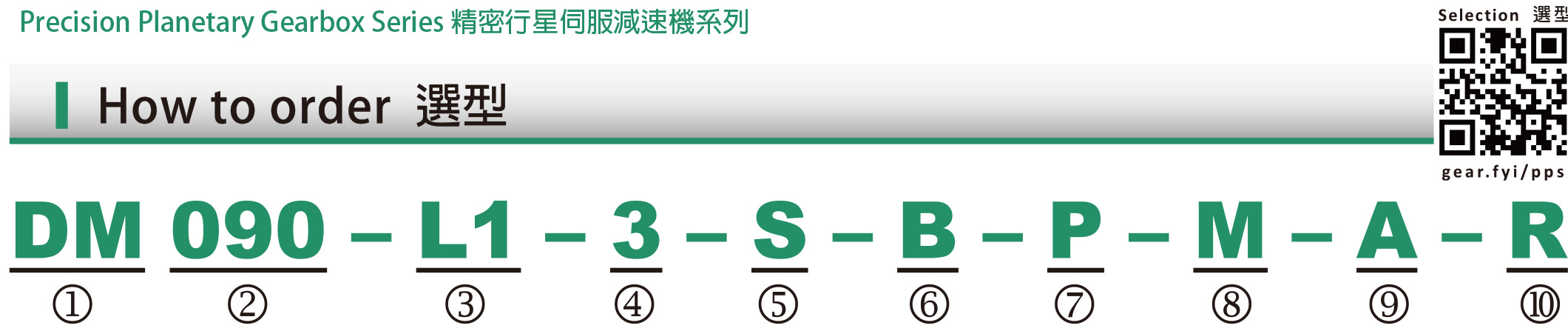

j |

Model |

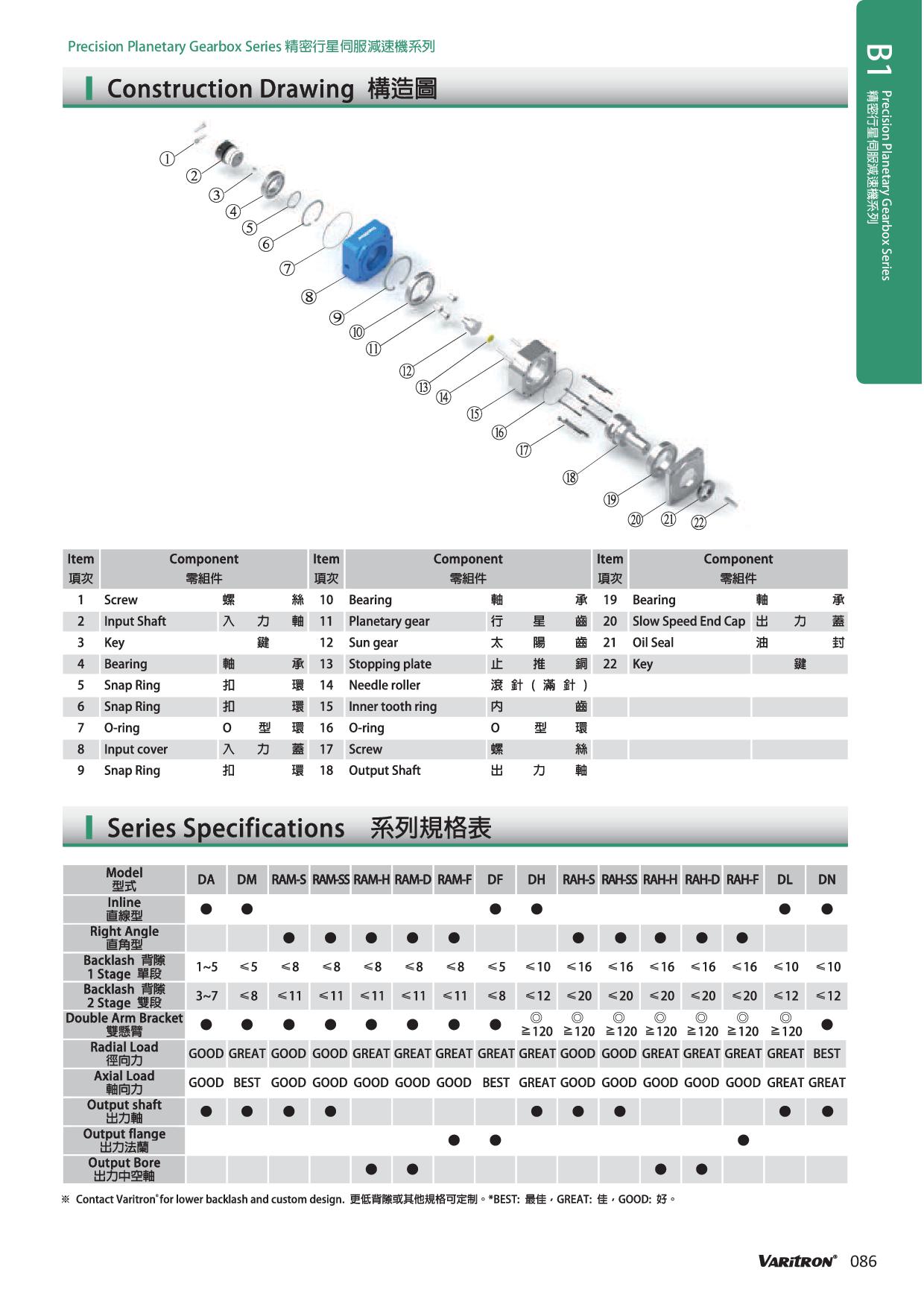

DA: Helical Gear High Precision Planetary Gearbox DM:Precision Planetary Gearbox DF:Precision Flange Type Planetary Gearbox DH:Standard Precision Planetary Gearbox DL:Standard Precision Planetary Gearbox DN:High R-A Load Standard Precision Planetary Gearbox RAM-S:Precision Shaft Output Spiral Bevel Gearbox RAM-SS:Precision Double Shaft Spiral Bevel Gearbox RAM-H:Precision Hollow Shaft Spiral Bevel Gearbox RAM-D: Precision Clamping Shaft Spiral Bevel Gearbox RAM-F: Precision Flange Spiral Bevel Gearbox RAH-S: Standard Precision Shaft Output Spiral Bevel Gearbox RAH-SS:Standard Precision Double Shaft Spiral Bevel Gearbox RAH-H:Standard Precision Hollow Shaft Spiral Bevel Gearbox RAH-D:Standard Precision Clamping Shaft Spiral Bevel Gearbox RAH-F: Standard PrecisionFlange Spiral Bevel Gearbox |

|

|

k |

Frame Size |

DN060,DN080,DN100,DN120… Refer to Gearbox Quick Selection Table Page 89. |

|

|

l |

Stage |

L1, L2, L3 |

|

|

m |

Ratio |

L1: 3 / 4 / 5 / 7 / 10 L2: 9 / 12 / 15 / 16 / 20 / 21 / 25 / 28 / 30 / 40 / 49 / 50 / 70 L3: 36 / 45 / 60 / 75 / 80 / 150 / 200 / 300 / 400 / 500 / 700 / 1000 |

|

|

n |

Motor Shaft Diameter (S) |

Customized according to customer requirement. |

|

|

o |

Motor Pilot Diameter (B) |

Customized according to customer requirement. |

|

|

p |

Motor Guide Depth (P) |

Customized according to customer requirement. |

|

|

q |

Installing Screw P.C.D (M) |

Customized according to customer requirement. |

|

|

r |

Installing Screw Size (A) |

Customized according to customer requirement. |

|

|

s

|

Motor Shaft Length (R) |

Customized according to customer requirement. |

|

Q &

A

Q: DN series planetary gearbox Reduction Ratio avaliable in single stage (L1) ?

A: 1:4, 1:5, 1:7, 1:9, 1:10

Q: DN series planetary gearbox Reduction Ratio avaliable in double stage (L2) ?

A: 1:16, 1:20, 1:25, 1:28, 1:35, 1:36, 1:40, 1:45, 1:49, 1:50, 1:63. 1:70, 1:81, 1:90

Q: DN series model number avaliable ?

A: DN060-L1, DN060-L2, DN060-L3, DN080-L1, DN080-L2, DN080-L3, DN100-L1, DN100-L2, DN100-L3

Q: What is the DN series APEX torque Planetary gearbox PHT ?

A: 918 Nm for DN150

Q: What is the interchange Dynamics model for DN High precision gearbox

A: PAII 042 / PAII 060 / PAII 090 / PAII 115 / PAII 142 / PSII A / PSII B / PSII C / PSII D / PSII E

Address:No.45, Lane 171, Chung Shin Road, Wuku District, New Taipei City, Taiwan

Tel:+886-2-29889598

Fax:+886-2-29850998

Email:[email protected]

Copyright 2014 © Varitron Engineering (Taiwan) Co., Ltd. All Rights Reserved.